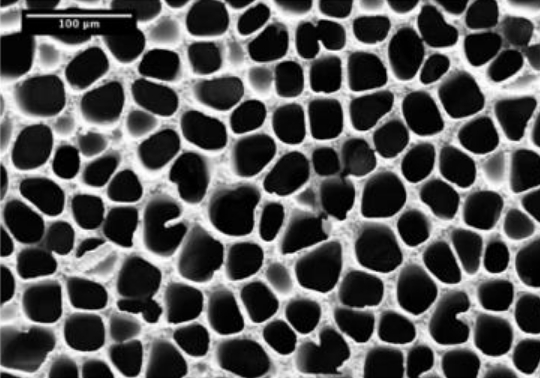

Shape memory and superelastic materials undergo a reversible martensitic transformation that allows them to return to their original state after deformation, either on the application of heat or the removal of stress. While zirconia-based ceramics can undergo this martensitic transformation, the volume expansion that accompanies the transformation can cause mismatched stresses at grain boundaries in polycrystalline systems, leading to cracking and premature failure. To increase the surface area to volume ratio, and thus circumvent this premature failure, this work uses directional freeze casting to incorporate columnar pores into ceria-stabilized zirconia ceramics, thereby producing honeycomb-like structures. These ceramics can be subjected to stresses up to 45 MPa and, depending on the ceria content, exhibit either shape memory or superelastic behavior under uniaxial compression. The studies include X-ray diffraction and Raman spectroscopy to track the extent of the martensitic transformations over different collection volumes, and explore that behavior over multiple cycles. Furthermore, in-situ Raman spectroscopy coupled with conventional uniaxial compression and diamond anvil cell loading confirm, for the first time, superelastic behavior in bulk-scale, polycrystalline, porous zirconia ceramic.

Zirconia Ceramic